Shuanghao: Professional Cap Mold Manufacturer & Precision Closure Solutions

At Shuanghao, we stand at the forefront of the mold-making industry as a dedicated, professional manufacturer of high-performance plastic cap molds. Our commitment to excellence, precision engineering, and deep understanding of global packaging needs make us the preferred choice for brands seeking reliability, innovation, and superior quality in their closure systems.

Our Manufacturing Advantages

What sets Shuanghao apart in a competitive market is a blend of technical expertise and client-centric values:

Precision Engineering & Advanced Technology: We utilize state-of-the-art CNC machining centers, EDM, and high-speed milling equipment to manufacture molds with exceptional accuracy and repeatability. Every mold is crafted to produce caps with perfect dimensional consistency and flawless functionality.

In-Depth Material Science Knowledge: Our team possesses extensive expertise in processing a wide range of polymers. We select and engineer molds specifically for materials like PP, PE, PET, HDPE, and specialty resins, ensuring optimal cap performance, durability, and finish.

Robust Mold Design Expertise: Our in-house design engineers focus on creating molds that are not only productive but also durable and maintenance-friendly. We prioritize designs that enhance cooling efficiency, reduce cycle times, and extend the overall lifespan of the mold.

Comprehensive Quality Assurance: From raw material inspection to final assembly, every manufacturing step undergoes rigorous quality checks. Our precision measuring instruments guarantee that every mold component meets the strictest tolerances and specifications.

End-to-End Solution Provider: We offer full-service support from initial concept and design validation to prototyping, mass production molding trials, and after-sales technical service. We partner with you to turn your cap concept into a market-ready reality.

Proven Experience Across Industries: Our molds produce caps for diverse sectors including bottled water, beverages, food, pharmaceuticals, cosmetics, and automotive chemicals, giving us versatile problem-solving capabilities.

Types of Plastic Caps We Specialize In

Our precision molds are designed to manufacture a comprehensive variety of plastic closure types, including:

Sport Caps (Push-Pull Caps): Ideal for on-the-go hydration, featuring a convenient flip-top lever for easy, one-handed operation.

Flip-Top Caps: Hinged closures that provide good resealability and user convenience, commonly used for personal care and food products.

Screw Caps: The most common closure for bottles, available in various thread finishes, diameters, and tamper-evident band options.

Dispensing Caps: Including disc-top caps for condiments, lotions, and oils, designed for controlled product application.

Tamper-Evident (TE) Caps: Incorporating breakaway bands or seals that provide visible proof of a product's integrity to consumers.

Child-Resistant (CR) Caps: Engineered with complex opening mechanisms to meet safety regulations for pharmaceutical and chemical products.

Anti-Counterfeit Closures: Featuring unique, difficult-to-replicate design elements for brand protection.

Why Choose Shuanghao?

Choosing Shuanghao means investing in a partnership built on quality, innovation, and reliability. We don't just build molds; we deliver solutions that enhance your production efficiency, protect your brand, and meet the evolving demands of the packaging world.

Contact us today to discuss your next plastic cap project and experience the Shuanghao advantage.

What is a Cap Mold?

A cap mold is a high-precision, custom-engineered tool used in the injection molding process to mass-produce plastic caps and closures for bottles, containers, and packaging. It defines the final cap's geometry, functionality, thread specification, and aesthetic finish.

Core Components & Structure of a Cap Mold

A standard cap mold is a complex assembly of several critical systems:

Cavity & Core System: The heart of the mold. The cavity forms the cap's exterior (top and sides), while the core forms the interior (threads, liners, and under-cap features). They are machined from premium tool steels (e.g., S136, H13, 420 Stainless) to extreme tolerances.

Molding Features:

Thread Forming: Core pins or unscrewing mechanisms create precise internal or external threads for sealing.

Tamper-Evident Band (TEB) Forming: Special grooves or mechanisms create the breakable ring that provides safety evidence.

Hinge Gates & Mechanisms: For flip-top or sports caps, these are intricately designed to allow repeated opening/closing.

Venting: Micro-channels allow air to escape during injection, preventing defects.

Ejection System: Pins, blades, or stripper plates that safely and cleanly eject the finished cap from the mold core without damage after cooling.

Cooling System (Temperature Control): A network of channels circulating water or oil to regulate mold temperature. This is critical for controlling cycle time, minimizing warpage, and ensuring consistent cap quality.

Gating System: The channel through which molten plastic enters the mold cavity. For caps, hot runner systems (with valve gates) are standard for efficiency and gate quality, though cold runners are also used.

Mold Base/Frame: The standardized plates (A-plate, B-plate) that house all the components and withstand immense clamping force from the injection molding machine.

Key Manufacturing Processes for Cap Molds

CNC Machining: For creating the primary shapes of cavities, cores, and plates with high precision.

Electrical Discharge Machining (EDM): Used for complex geometries, sharp corners, and fine texturing (e.g., matte finishes, logos).

High-Speed Milling: For fine finishing and detailed contouring.

Grinding & Polishing: Achieves the required surface finish on the molding surfaces, which is directly transferred to the plastic cap.

Assembly & Fitting: Skilled technicians assemble all components, ensuring perfect alignment and smooth operation of moving parts (e.g., unscrewing mechanisms).

Cap Mold Classification by Production Type

Family Molds: Multiple cavities producing different cap styles/sizes in one shot. Lower efficiency, good for prototyping or low-volume variants.

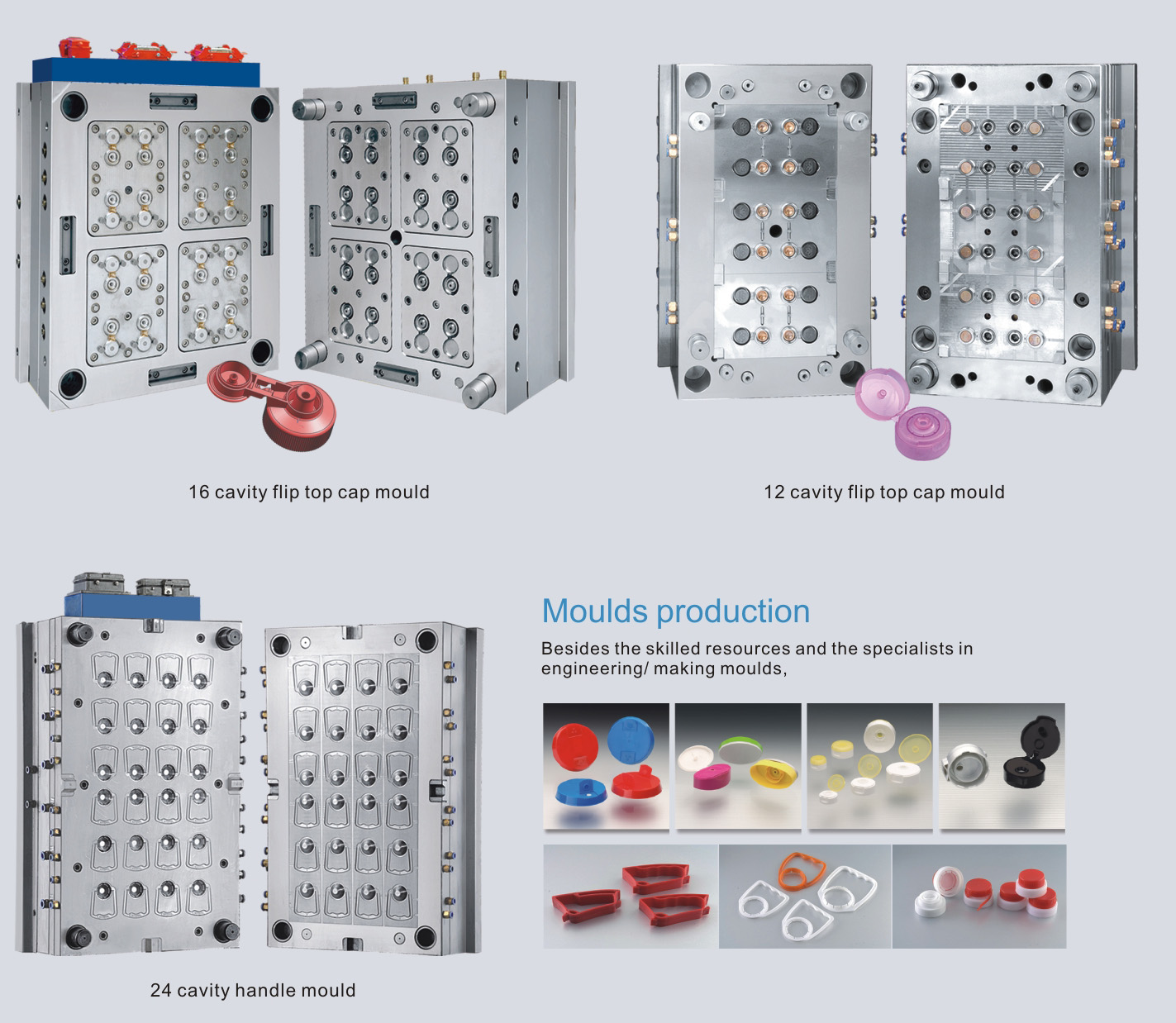

Multi-Cavity Molds: Identical cavities producing many identical caps per cycle. Standard for high-volume production (e.g., 32, 48, 96 cavities).

Stack Molds: Two or more molding levels stacked, doubling output without increasing the machine's clamp area. Used for very high-volume, simple closure production.

Why Cap Mold Design is Critical

Thread Integrity: Must match the bottle finish perfectly for leak-proof sealing.

Draft Angles: Essential for easy ejection without scratching or dragging.

Shrinkage & Warpage Prediction: Material-specific shrinkage must be precisely calculated and compensated for in the mold design.

Cycle Time Optimization: Cooling channel design is paramount to minimize the time between injection and ejection.

Tool Longevity: Design and material choice affect the mold's life, which can be millions of cycles.