Mineral Water Caps & Closure Molds’

hallmarks include extremely fast cycle times, (sometimes less than 2 seconds).

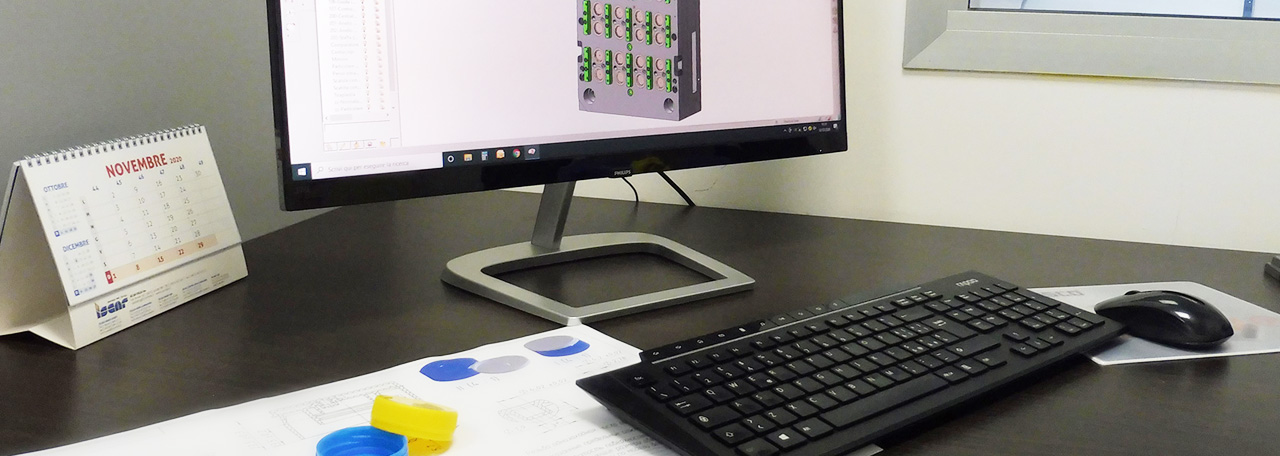

Plastic Mineral Water Cap Mould

Plastic Mineral Water Cap Mould hallmarks include extremely fast cycle times, (sometimes less than 2 seconds). Mold cooling becomes extremely important to achieve these cycles as well as a smooth and even ejection of the parts from high cavitation molds which are some of StackTeck’s strengths.We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory.AD/CAM/CAE system for designing and engineering mould products.We design and use standard moul frame and use pricision 3D printer and CNC tooling machine to make parts, in order to ensure the quality of the moulds. We also wholesale Plastic cap, other molds and service.

Here is the technical parameters of compression cap mould’s molding speed

| Machine Series | Cap Diameter | Cap Height | Voltage& Frequency | Capacity | Machine Dimension | Machine Weight |

| CCM-JP24G(Standard) | 20-70mm | 10-30mm | 380V/50Hz /60Hz | 24000pcs/h | 5.5*1.9*2.2m | 7000kg |

| CCM-JP24H(High Speed) | 20-50mm | 10-30mm | 380V/50Hz /60Hz | 35000pcs/h | 7.0*2.7*2.6m | 11000kg |

| CCM-JP36H(High Speed) | 20-50mm | 10-30mm | 380V/50Hz /60Hz | 60000pcs/h | 8.0*4.2*2.6m | 15000kg |

| CCM-JP48H (High Speed) | 20-40mm | 10-30mm | 380V/50Hz /60Hz | 80000pcs/h | 9.5*4.2*2.6m | 15000kg |

Current Clients

years of experience

awards winning

Offices Worldwide

Mineral Water Closure cap Molds

Cap mold with 38mm diameter seal, made of stainless material that gurantees minimal use over time.

The hot chamber and the nozzles have been designed and bult in –house in the company itself, whereas all components have been designed specifically for the type of mold to be made.

All the printing parts are tempered and coated, ensuring the functionality and durability of the components.

All the parts shown are designed to be interchangeable with each other, so as to reduce the response time in case of problems.