Sports Cap Water Bottle Molds - China Manufacturers, Suppliers, Factory

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Sports Cap Water Bottle Mould, Plastic Caps For Tubing Mould, Conditioner Cap Mould, Pe Bottle Caps,Conmmon Plastic Cap. We are looking forward to forming successful business relationship with new clients in the near future! The product will supply to all over the world, such as Europe, America, Australia,Jordan, Iran,Angola, Melbourne.Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

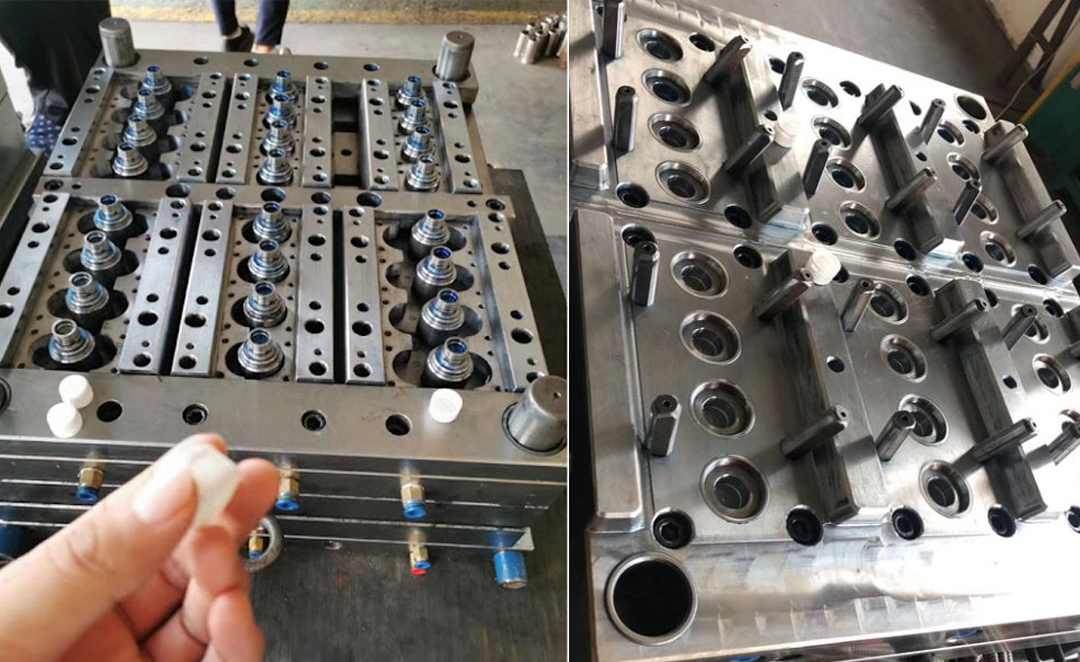

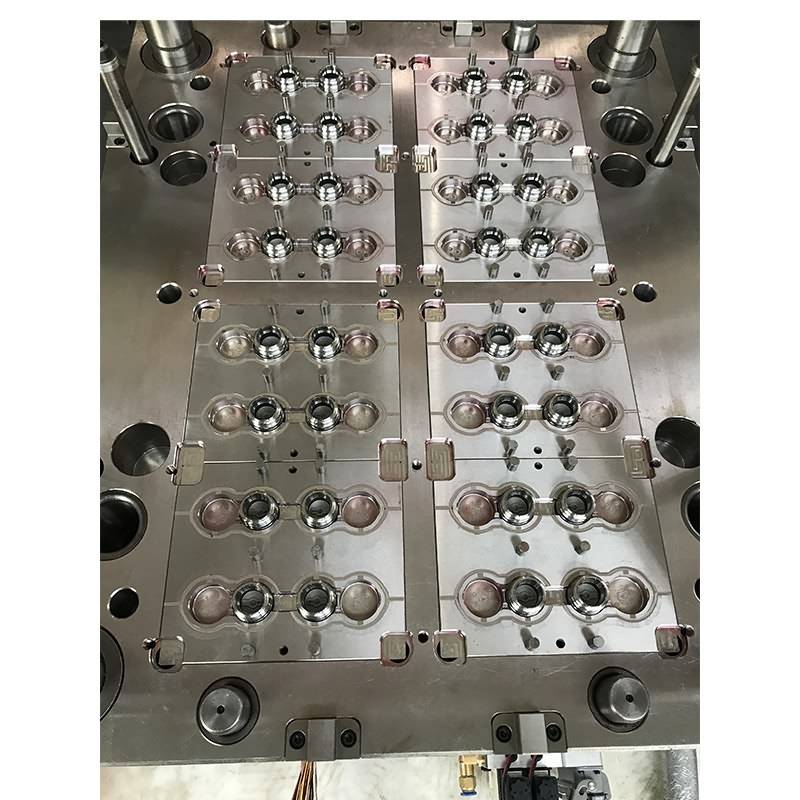

1, Mould base is made of LKM frame, and HASCO standard frame, all components are with DME or HASCO standard.

2, We have a wide useage of mold steel, both local and improted, 50C, P20,420H,2083,2344, S136, from ASSAB, LKM,etc.heat treatment to HRD 48~52 HRC, nitried all sliders and inserts, use Berylium Copper in corners to improve cooling.

3, We supply 2D mold drawing 2D/3D cap drawing and details layout.

4, We make cold runner mold, hot runner mold(Husky,Moldmaser,DME and YUDO), etc. Our engineer and technican are always keep studying and get more and more experienced and professional on mold making skills.

5, We have a wide usage on plastic material, especially for those may cause worse deformation,

bad filling, worse part surface, we have our ways to control the mold to have better parts.

6, We ensure the mold life to customers, we provide steel and material conformity, certicate to customers.

7, Our advanced equipment and high effective mangement give customer stable lead time.