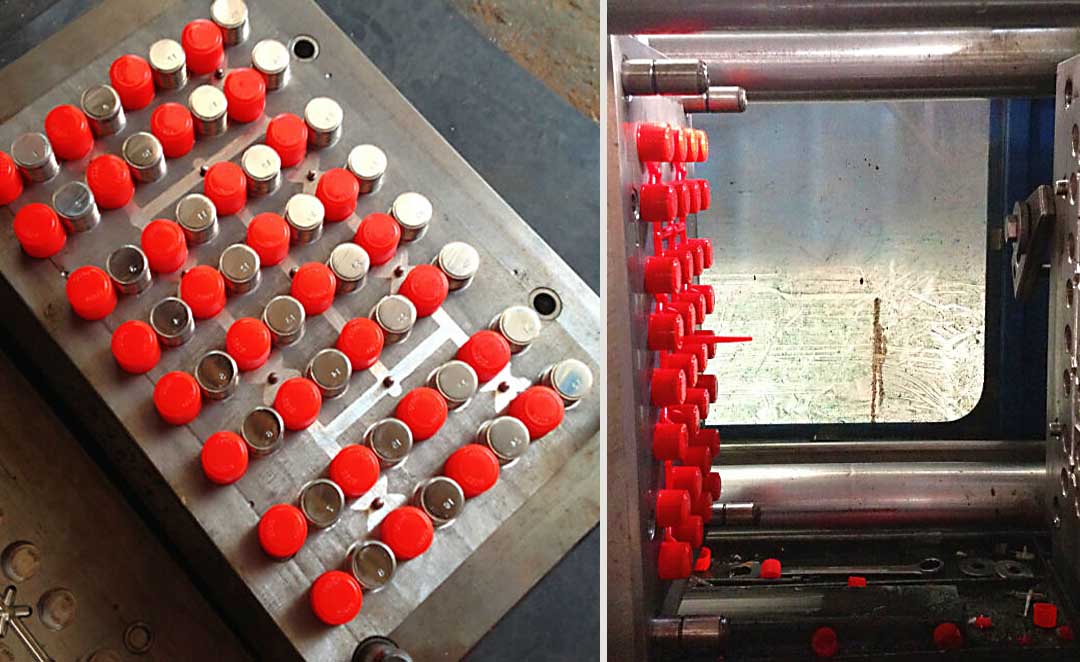

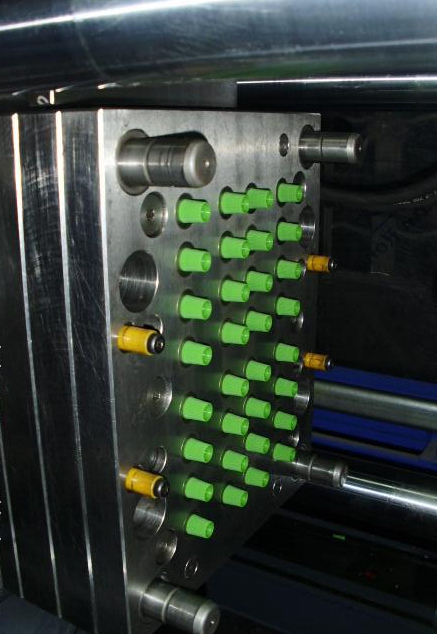

Bottle cap mould Shuanghao mould

1). INTRODUTION

1. Application: all kinds of food bottles, washing bottles,fruit juice bottles, cup,glass bowl, milk bottle, ordinary bottle, Beverage bottle,etc.

2. Materials: PE,PP,

3. Customize Design is available, for instance,Engraved LOGO, AD. Providing production of caps and related accessories,such as handle

4. Mould materials: P20, 2316

5. Heat Treatment Hardness: HRC50 - 60

6. Mold cavity is replaceable,which is convenient to change the label

7. Operating Life: At least 1 million times life-time guaranteed

8. One year spare parts

| Technique | plastic injection mould |

| Surface treatment | polishing, mirror surface, frosted surface or texture surface |

| Material | mould : S50C , 718, P20, German 2316 , S136, 8407, AL7075

products: PP , PE , PET. |

| General size | according to ur 3D model (we have design team for ur customized product) |

| Design software | UG, PRO-E, CAD , SOLIDWORKS |

| Cavity number | Singer cavity , multiple cavities or one mould with different products |

| mould test | All moulds will be well test before the shipments |

| packages | Plastic film to avoid the water corrosion the mould and strong wooden case avoid any damages in the long transportation |

After-sales service:

1)Provide 1 year of technology service after mould delivery.

2)Provide mould spare parts within 1 year after mould delivery.

3)Provide mould maintenance free of charge within 1 year after mould delivery.(Except of man-made damage).

4)Provide 3 years of maintenance service after warranty period (collect appropriate cost).

5)If the mould problem is caused by human reasons, We will charge an appropriate cost for maintenance.