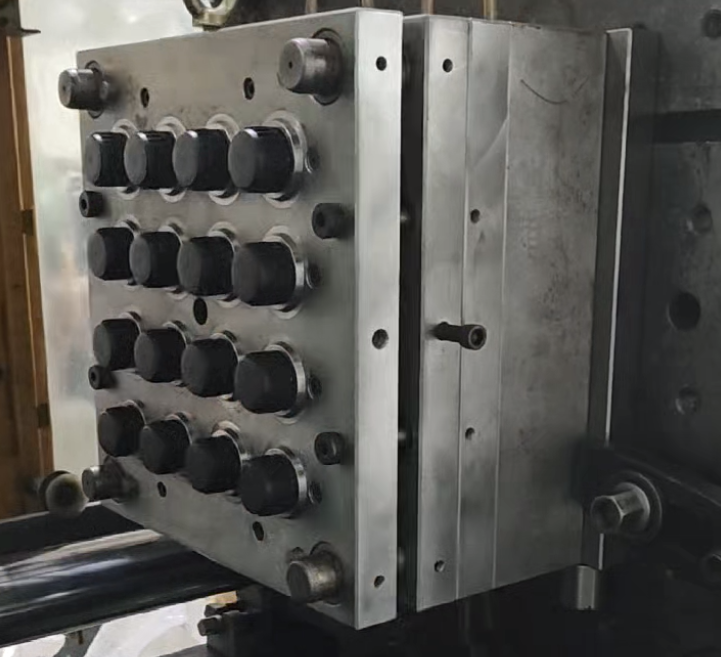

High-Efficiency 38mm Oil Cap Mould with 16-Chamber Hot Runner System by SHUANGHAO

In the competitive packaging industry, maximizing production efficiency and ensuring consistent quality are paramount. SHUANGHAO, a professional manufacturer specializing in cap moulds, presents its premium solution: the 38mm Oil Cap Mould integrated with an advanced 16-Chamber Hot Runner System. This mould is engineered for manufacturers in the lubricant, automotive, and chemical sectors who demand reliability, speed, and precision.

Key Features & Benefits

1. Standard 38mm Design for Market Needs

This mould is precision-engineered to produce standard 38mm oil caps and lubricant caps,

ensuring perfect compatibility with most containers in the market.

SHUANGHAO's expertise guarantees that each cap, whether a simple

screw-top or one with an internal seal, meets exact dimensional and

performance specifications for a leak-proof closure.

2. 16-Chamber Hot Runner for Maximum Productivity

The heart of this system is its 16-cavity hot runner. This technology eliminates sprues and runners, leading to 100% material utilization

with no waste. By delivering molten plastic directly to each gate, it

significantly reduces cycle times. The "one-shot, 16-caps" capability

dramatically increases output, providing a substantial boost to your

production capacity and ROI.

3. Built for Stability and Continuous Operation

SHUANGHAO understands that downtime is costly. Our 38mm oil cap mould is constructed from high-grade, hardened steels (such as H13, S136) for exceptional wear and corrosion resistance. The 16-chamber hot runner

system features individual nozzle temperature control, ensuring perfect

melt balance across all cavities. This robust design minimizes defects

and ensures stable, uninterrupted 24/7 production runs.

4. Intelligent Engineering for Superior Quality

Balanced Flow Design: Ensures uniform filling, packing, and cooling in all 16 cavities, resulting in consistent cap weight, dimensions, and wall thickness.

Optimized Cooling Circuitry: Efficient cooling channels enable faster heat removal, shortening the cycle time and increasing overall productivity.

Automation-Ready Design: The mould is designed for seamless integration with robotic part-removal systems, facilitating full automation and reducing labor costs.

Why Partner with SHUANGHAO?

SHUANGHAO is not just a supplier; we are your strategic partner in cap mould manufacturing. With a deep focus on cap moulds, we provide end-to-end solutions from design and prototyping to mass production and support. Our engineering team works closely with you to customize the mould according to your specific resin, injection molding machine, and production goals.

Choosing SHUANGHAO means selecting:

Proven Quality: Rigorous testing and inspection on every mould.

Cost-Effectiveness: Higher output and reduced waste lower your cost-per-part.

Long-Term Durability: Premium materials and craftsmanship ensure a long service life.

Expert Support: Comprehensive technical support and responsive after-sales service.