Innovation in Every Thread: Your Partner for High-Performance Plastic Bottle Cap Molds

In the fast-paced world of packaging, the humble bottle cap plays a critical role in product integrity, user experience, and brand identity. At [Shuanghao mould], we understand that perfection begins with the mold. We are a specialized manufacturer dedicated to engineering and producing high-precision plastic bottle cap molds that set the industry standard for quality, performance, and reliability.

The Heart of Packaging: Why Your Cap Mold Matters

A bottle cap is more than just a closure; it's a complex sealing system. The mold used to create it must be impeccably designed and machined to ensure:

Perfect Seal Integrity: Preventing leaks and preserving product freshness.

Consistent Thread Quality: Ensuring smooth application and removal, every time.

Aesthetic Excellence: Delivering a flawless surface finish that enhances your brand.

High-Speed Production: Built for durability to withstand high-volume injection molding cycles.

Our Cap Mold Manufacturing Expertise

With years of experience serving global clients, we have honed our process to deliver exceptional value from concept to production.

1. Collaborative Design & Engineering

Our process begins with a deep understanding of your needs. Our engineering team utilizes advanced CAD/CAM software to design custom bottle cap molds

that optimize material flow, cooling, and ejection. We focus on

designing for manufacturability (DFM) to ensure your mold is efficient,

cost-effective, and built for longevity.

2. Precision CNC Machining

Quality is machined into every component. Our state-of-the-art workshop is equipped with 5-axis CNC machining

centers, EDM, and high-speed milling equipment. This allows us to

achieve ultra-tight tolerances and perfect surface finishes, critical

for complex cap features like tamper-evident bands (TE bands), internal

threads, and liners.

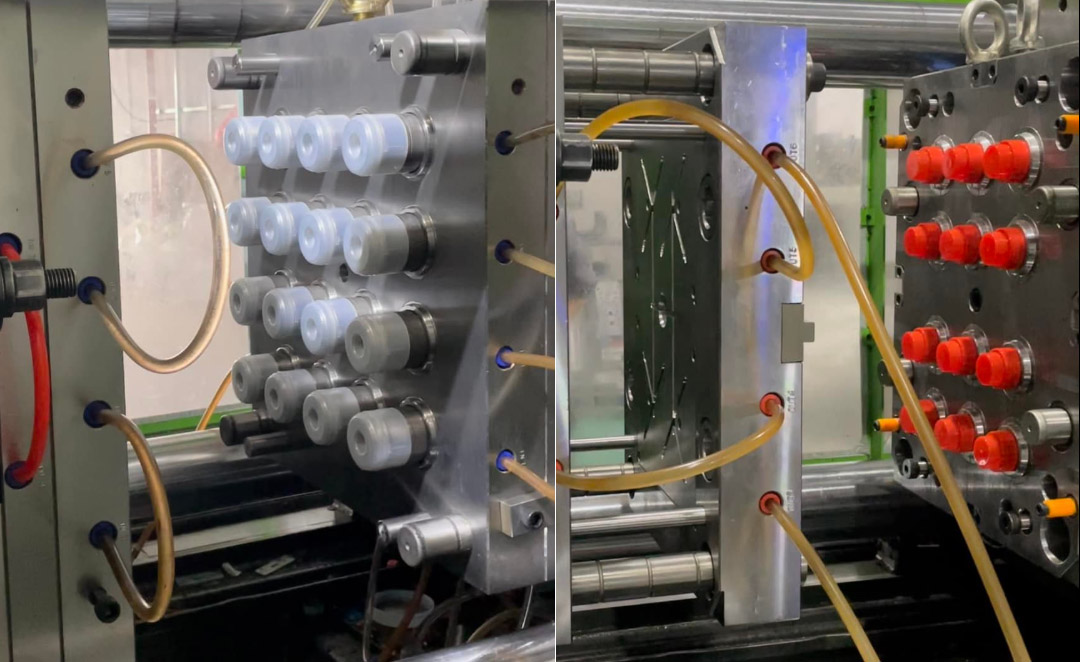

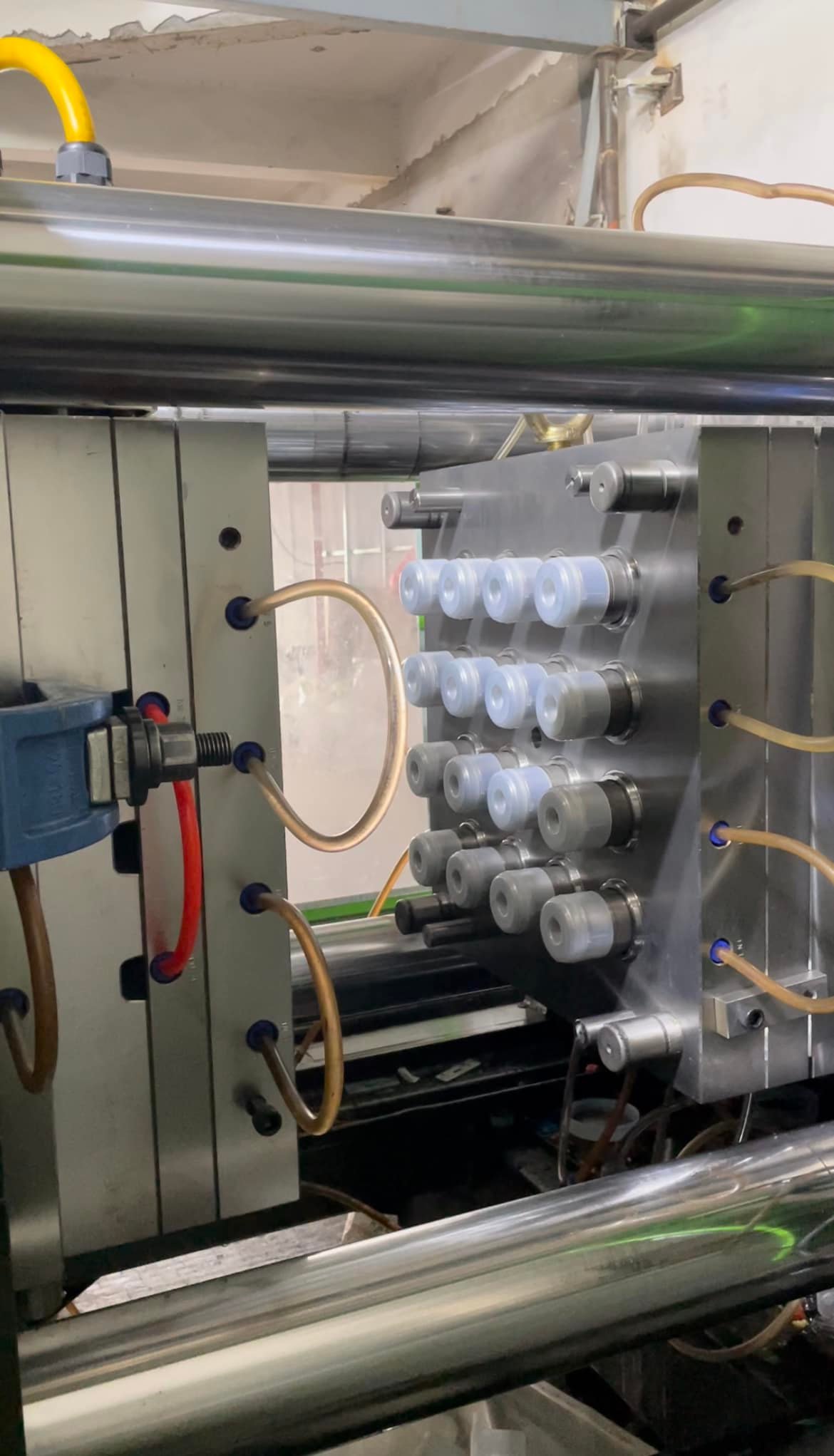

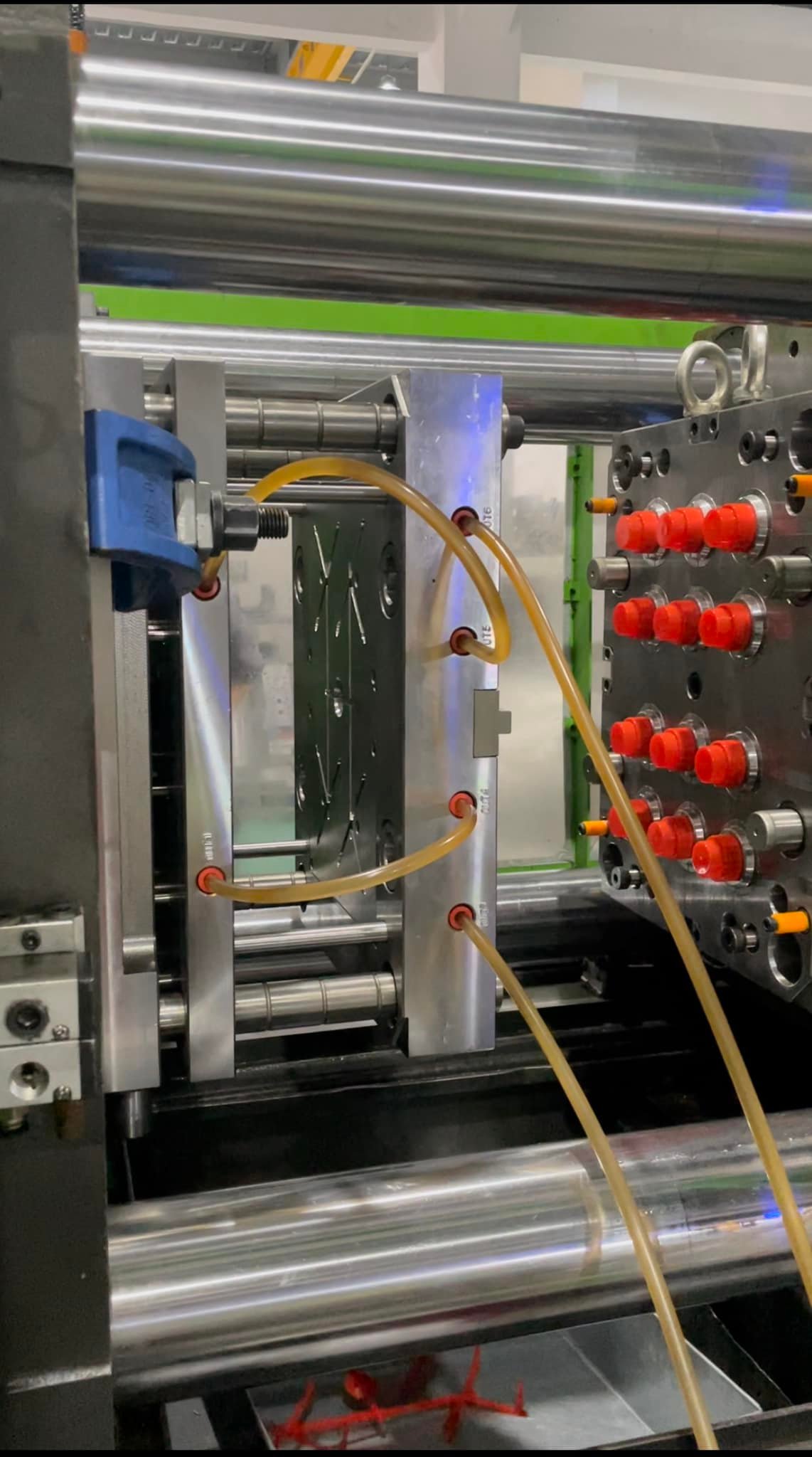

3. Comprehensive Mold Testing

Before

delivery, every mold undergoes rigorous testing in our production

facility. We run sample cycles to validate performance, check part

dimensions, and ensure the caps meet all functional requirements. This

step guarantees a seamless transition to your full-scale production.

4. Full Support & Maintenance

Our partnership doesn't end at delivery. We provide comprehensive technical support and mold maintenance services to keep your production running smoothly and extend the life of your tooling investment.

Industries We Serve

Beverage Industry: Carbonated soft drink (CSD) caps, water bottle caps, sports drink closures.

Pharmaceutical & Healthcare: Child-resistant caps, dispensing closures, tamper-evident medicine bottles.

Food & Consumer Goods: Screw caps for condiments, oils, dairy products, and household chemicals.

Personal Care & Cosmetics: Lotion pumps, flip-top caps, cream jars, and elegant cosmetic closures.

Why Choose [Shuanghao mould] as Your Mold Partner?

Deep Technical Expertise: Specialized knowledge in cap and closure mold design.

Quality Materials: We use only premium-grade mold steels (e.g., Stainless Steel, H13) for maximum durability.

On-Time Delivery: We understand your time-to-market pressures and commit to reliable project timelines.

Global Standards: Our molds are built to export quality standards, serving clients worldwide.

Custom Solutions: From simple screw caps to highly technical closure systems, we develop the perfect solution for you.

Ready to Secure the Perfect Cap for Your Product?

Leverage our expertise to create a mold that drives your packaging success. Contact us today for a consultation and a competitive quote.