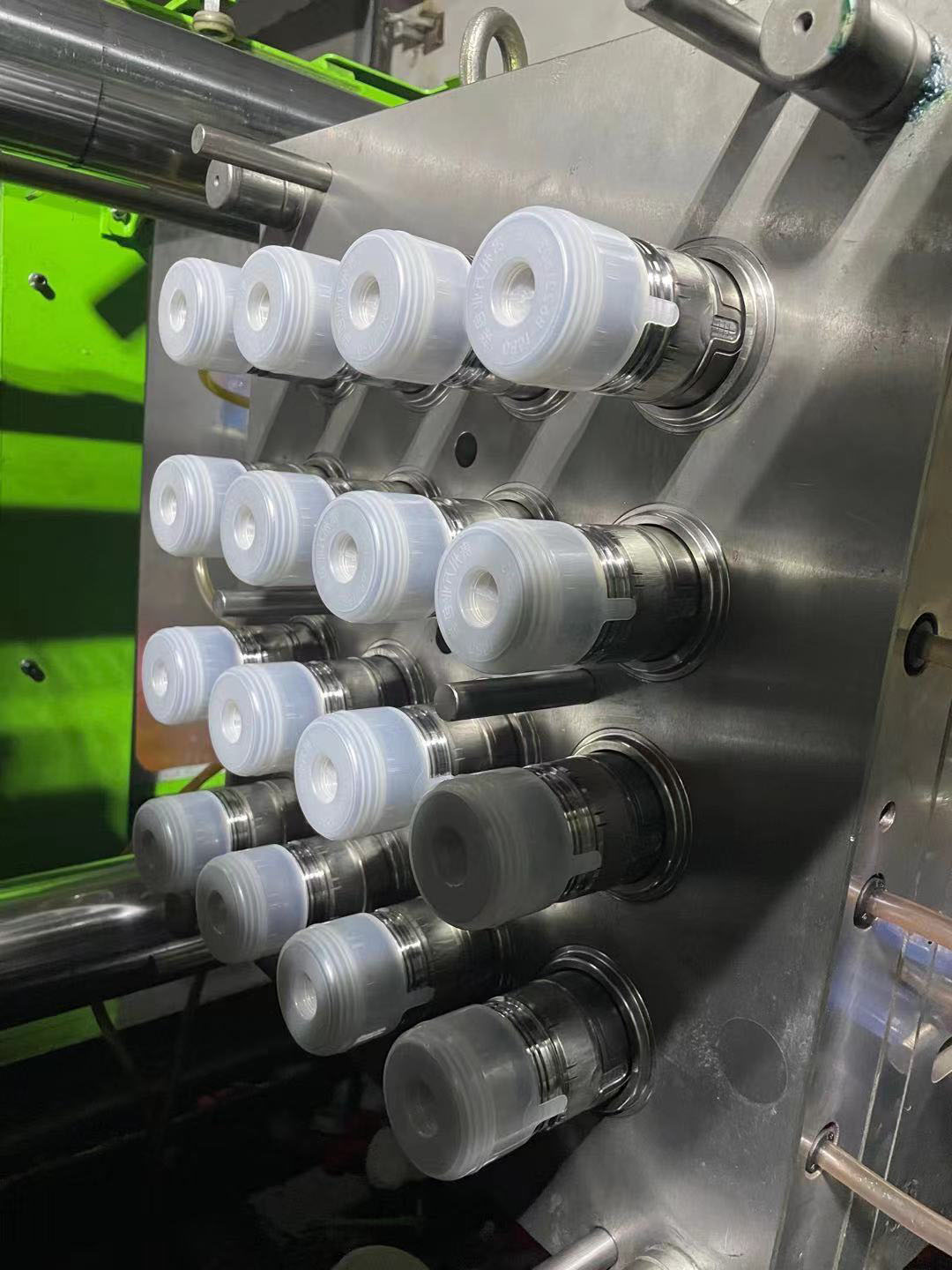

Quality Analysis of Plastic Cap Molds

In the process of injection molding of plastic caps, due to mold, materials and equipment, etc., the parts may be burred, lack of material, etc., which will increase the failure rate of parts. Next, let's take a look at some common quality analysis questions!

Question 1: There is a shortage of material. The lack of material generally refers to the situation in which the shape of the part does not conform to the design due to the filling of the cavity of the mold during the processing of the plastic.

Equipment reasons: The cause of equipment shortage is mainly the nozzle part, which is generally blocked by the nozzle; the quick solution is to clean the nozzle. In addition, the leakage of the nozzle can also lead to lack of material, but such failures generally require the replacement of a new nozzle.

Mold reasons: Generally caused by the internal exhaust of the mold is not smooth. Since the air accumulated in the cavity cannot be discharged, the plastic filling amount is insufficient, resulting in shortage of materials. The solution is to reduce the filling speed of the plastic or to increase the corresponding vent hole in the mold.

Problem 2: When the problem of the flashing material is not solved in time, the flashing edge will be enlarged; and the flashing of the insert backlash and the pusher hole will cause the plastic piece to be stuck on the mold and affect the parting.

Equipment reason: The machine's own clamping force is not enough, which will cause the mold to not be properly compressed. Generally, when selecting the model of the injection molding machine, the rated clamping force of the machine must be greater than the tension formed by the axial cross-sectional area of the injection molded part at the time of injection, otherwise the mold release will occur and the phenomenon of flashing will be formed.

Mold reasons: Generally caused by the irrationality of the mold design, such problems are more difficult to solve, and it is necessary to redesign the mold.

Question 3: Plastic shrinkage occurs. Shrinkage is the most common occurrence of defects on the surface of the finished product, and most of the drywall thickness occurs.

Equipment reason: The injection molding machine has less speed and pressure holding time, which makes the plastic parts less fluid. The plastic parts that first enter the mold cavity are cooled faster, and there is not enough time for the pressure to be filled. To solve this problem, a higher injection pressure is required.

Mold cause: The exhaust inside the plastic cap mold is not smooth, and it will cause unnecessary air in the cavity to be excluded. The solution is to maintain the mold and increase the vent.