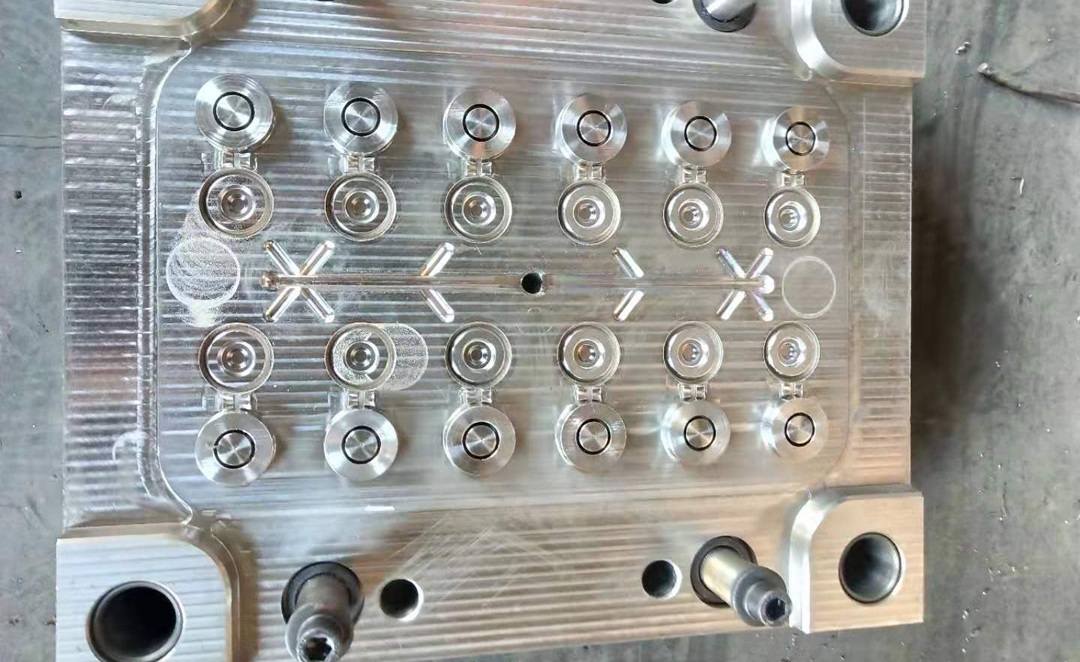

Plastic flip-top cap molds design and manufacturing

Relying on strict quality standards and strong technical innovation capabilities, we have established long-term cooperative relationships with many customers at home and abroad, and designed and manufactured high-quality flip cap molds for them.

1. We attach great importance to the bow hinge design to ensure its flexibility and not easy to break.

2. We use Moldflow analysis to simulate the entire injection molding process to ensure high yield of products during mass production.

3. The hot runner system uses German heating components with excellent performance to ensure uniform melt flow and pressure in all cavities.

4. Each cavity independently controls the heat to ensure a uniform temperature.

5. Standard interchangeable mold inserts.

6. All parts are machined with high precision CNC equipment with a tolerance of less than 0.02mm.

7. High-hardness stainless steel mold core and cavity, double anti-corrosion and anti-rust, ensuring high precision and long mold life.

8. Each cavity and core has an independent cooling system that shortens the production cycle.

9. Special water pipe design eliminates water pipe leakage.

10. It is convenient to change the cavity number identification of the cavity and the core, so that the customer can quickly find and replace it correctly.

11. Our mold parts are available in DME, HASCO or other standards to make it easy for customers to find replacement parts on the market. These standards are internationally versatile and easy to purchase and easy to replace.

12. We can provide inspection reports on important dimensions of CMM molds.

13. In-mold automatic flip or automatic flip can be designed according to customer requirements.

14. Mould life exceeds 2 million molds.